Views: 0 Author: Site Editor Publish Time: 2025-10-21 Origin: Site

Metal stamping is crucial in automotive stamping. It shapes metal sheets into precise components. This process ensures vehicles meet high standards for safety and reliability. In this post, you'll learn about stamping techniques, their importance, and how they enhance automotive manufacturing.

Traditional metal stamping remains the backbone of automotive manufacturing. It involves shaping metal sheets by pressing them between dies. Common methods include:

● Blanking: Cutting flat shapes from metal sheets.

● Piercing: Creating holes or cutouts.

● Bending: Forming angles or curves.

● Coining: Compressing metal to improve surface finish and detail.

These techniques rely on mechanical presses, which deliver high force to shape metals quickly and accurately. They have proven reliable for decades, producing parts like brackets, panels, and structural components.

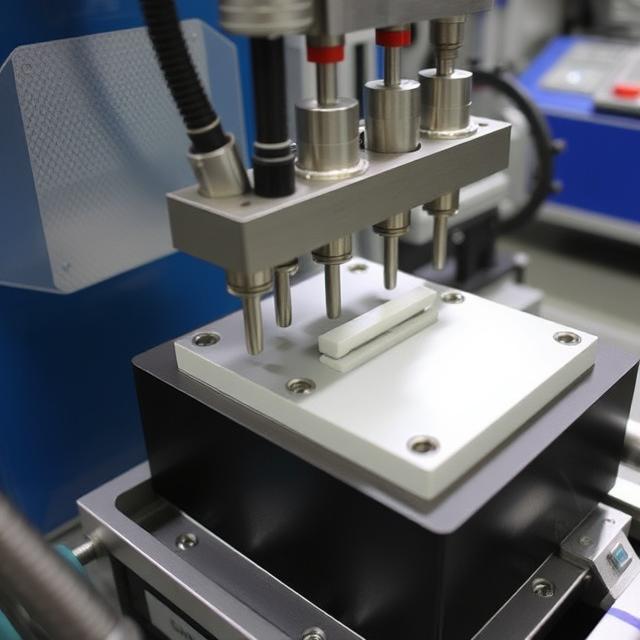

Recent advancements have revolutionized metal stamping, boosting precision and efficiency. Some notable technologies include:

● Electromagnetically Assisted Stamping: Uses electromagnetic forces to reduce the force needed, improving metal formability and reducing die wear.

● Hydroforming: Employs fluid pressure to shape metal into complex geometries, ideal for lightweight automotive parts.

● Servo-Driven Presses: Offer precise control over speed and force, enabling intricate part designs and reducing cycle times.

● Progressive Die Stamping: Combines multiple stamping operations into one continuous process, increasing throughput and consistency.

These innovations enable manufacturers to work with advanced materials and produce components that meet stricter quality and safety standards.

The integration of advanced stamping technologies delivers several key benefits:

● Improved Part Quality: Enhanced control reduces defects and ensures consistent dimensions.

● Greater Design Flexibility: Complex shapes and thinner materials become feasible.

● Increased Production Efficiency: Faster cycles and reduced downtime lower costs.

● Material Savings: Precise forming minimizes scrap and waste.

● Enhanced Tool Life: Reduced wear on dies decreases maintenance needs.

Together, these benefits help automotive manufacturers meet growing demands for safety, performance, and cost-effectiveness.

Tip: Invest in servo-driven presses and electromagnetically assisted stamping to boost precision and reduce production costs in automotive metal stamping operations.

Metal stamping plays a vital role in producing numerous automotive parts. It shapes metal sheets into precise components used throughout vehicles. Common stamped parts include:

● Floor Mat Securement Brackets: Hold mats firmly in place.

● Horn Buttons: Provide reliable activation for vehicle horns.

● Rearview Mirror Mounting Plates: Secure mirrors to vehicle frames.

● Steering Wheel Components: Include structural elements and trim.

● Brake System Parts: Such as brackets and mounting hardware.

● Fuel Injectors and Pressure Regulators: Critical for engine performance.

● Seat Latches: Ensure passenger safety by locking seats securely.

Each part requires exact dimensions and durability to meet automotive standards. Metal stamping ensures consistent quality and repeatability in mass production.

Beyond original equipment manufacturing (OEM), metal stamping supports the growing aftermarket parts sector. Custom aftermarket parts allow vehicle owners to personalize or upgrade their vehicles. Metal stamping offers:

● Cost-Effective Production: Enables small to medium batch runs affordably.

● High Precision: Maintains tight tolerances for fit and function.

● Material Versatility: Works with various metals to suit performance needs.

● Rapid Turnaround: Accelerates time from design to finished product.

This flexibility helps manufacturers meet diverse consumer demands while maintaining safety and reliability. Aftermarket parts like custom brackets, trim pieces, and mounting plates benefit from metal stamping's efficiency.

Safety and reliability remain top priorities in automotive manufacturing. Metal stamping contributes by producing parts that meet rigorous industry standards. Key factors include:

● Precision Tolerances: Ensure parts fit correctly and perform as intended.

● Material Strength: Supports structural integrity under stress.

● Consistent Quality: Reduces defects that could cause failures.

● Compliance Testing: Parts undergo strict inspections for safety certifications.

Automotive metal stampers employ advanced quality control methods and sophisticated stamping technologies. These efforts guarantee that stamped components withstand real-world conditions, protecting passengers and vehicle performance.

Metal stamping is highly efficient in using raw materials. The process precisely cuts and shapes metal sheets, minimizing scrap. Dies are designed to nest parts closely, squeezing maximum usage from each sheet. This reduces waste and lowers material costs. Compared to other manufacturing methods, stamping generates less leftover metal, helping manufacturers save money and support sustainability goals.

Speed and repeatability make metal stamping a cost-effective choice. Automated presses run continuously, producing thousands of parts per hour. The process requires minimal manual labor once set up, reducing labor costs. Progressive dies perform several operations in one run, cutting cycle times and boosting throughput. Quick changeovers between dies also enable flexible production for different parts without long downtime.

Moreover, stamping produces consistent parts that meet tight tolerances, lowering rejection rates and rework expenses. Efficient quality control tools help detect defects early, ensuring smooth production flow. All these factors combine to keep manufacturing costs down while maintaining high quality.

The savings from reduced material waste and efficient production translate into lower prices for consumers. Metal stamping enables mass production of durable automotive parts at scale, driving down unit costs. These savings help manufacturers offer competitively priced vehicles and replacement parts without compromising safety or performance.

Additionally, cost-effective stamping supports innovation by allowing automakers to invest in advanced materials and designs. This balance of affordability and quality benefits consumers through better, safer vehicles and more accessible aftermarket parts.

The metal stamping market in automotive is set to grow rapidly. Industry forecasts estimate global demand will near $300 billion by 2025. This growth stems from the increasing use of stamped metal parts in vehicles worldwide. Automakers require more complex, lightweight, and durable components, making metal stamping essential. Additionally, the rise of electric vehicles (EVs) and autonomous cars fuels demand for new stamped parts designed for innovative systems.

Several factors drive this expansion:

● Technological Advances: New stamping methods like electromagnetically assisted stamping improve precision and reduce costs.

● Material Trends: Growing use of lightweight alloys such as aluminum and titanium supports fuel efficiency and emissions goals.

● Automotive Production Growth: Increasing vehicle production in emerging markets boosts metal stamping needs.

● Aftermarket Growth: Demand for custom and replacement parts rises as vehicle fleets age.

● Sustainability Focus: Metal stamping’s low waste and recyclability align with green manufacturing initiatives.

Together, these factors create a strong foundation for sustained industry growth.

Innovations play a key role in expanding metal stamping’s capabilities:

● Hybrid Electromagnetically Assisted Stamping: Reduces required force, enabling complex shapes and thinner materials.

● Servo-Driven Presses: Offer precise control over speed and force, increasing quality and reducing cycle times.

● Hydroforming: Uses fluid pressure to form intricate, lightweight parts, improving vehicle performance.

● Advanced Tooling Materials: Enhance die life and reduce maintenance costs.

● Integration with Automation: Robotics and AI improve consistency and throughput while lowering labor costs.

These technologies help manufacturers meet stricter safety standards, reduce costs, and innovate vehicle designs.

Automotive metal stamping uses a variety of metals and alloys, chosen for strength, weight, and cost. The most common include:

● Steel: Carbon steel dominates due to its strength, durability, and affordability. It’s ideal for structural parts like chassis and reinforcements.

● Stainless Steel: Offers corrosion resistance and is used in exhaust systems and trim components.

● Aluminum: Lightweight and corrosion-resistant, aluminum helps reduce vehicle weight, improving fuel efficiency. It’s common in body panels and engine parts.

● Copper and Copper Alloys: Used for electrical components due to excellent conductivity.

● Titanium: Strong but expensive, titanium appears in high-performance or specialty parts requiring strength and light weight.

● Brass and Bronze: Often used in fittings and bushings for wear resistance.

Each metal or alloy suits specific automotive needs, balancing performance, cost, and manufacturability.

Metal alloys provide several benefits in automotive stamping:

● Enhanced Strength-to-Weight Ratio: Alloys like aluminum and titanium reduce vehicle weight without sacrificing strength, aiding fuel economy and handling.

● Improved Corrosion Resistance: Stainless steel and aluminum alloys resist rust, extending part life and reducing maintenance.

● Greater Formability: Some alloys allow more complex shapes, enabling innovative designs.

● Thermal and Electrical Properties: Copper alloys handle electrical and heat conduction efficiently, critical for modern vehicles.

● Durability: Alloys often resist wear and fatigue better than pure metals, ensuring long-lasting parts.

These advantages help automakers meet safety, efficiency, and environmental standards.

Material choices evolve as automotive demands shift. Current trends include:

● Lightweighting: Growing use of aluminum and high-strength steel alloys to reduce vehicle mass and improve fuel efficiency.

● Advanced High-Strength Steels (AHSS): These steels offer superior strength and ductility, allowing thinner parts that maintain safety.

● Multi-Material Designs: Combining metals like steel and aluminum in one assembly to optimize performance and cost.

● Recyclable Materials: Increasing use of recyclable metals supports sustainability goals.

● Exotic Alloys: Titanium and magnesium alloys gain traction for specialty applications in electric and luxury vehicles.

Automotive manufacturers continue adapting material strategies to balance performance, cost, and environmental impact.

Metal stamping is crucial for automotive assembly, offering efficient production and high-quality parts. It includes traditional and advanced techniques, ensuring precision and cost-effectiveness. The future of automotive assembly will rely heavily on metal stamping due to increasing demand for lightweight, durable components. As the industry evolves, stamping technologies will continue to play a vital role. Zonze provides innovative solutions that enhance stamping processes, delivering exceptional value and supporting the automotive industry's growth and sustainability.

A: Automotive stamping is a manufacturing process that shapes metal sheets into specific components used in vehicles, employing techniques like blanking, piercing, and bending.

A: Automotive stamping enhances production efficiency by enabling fast, repeatable processes that minimize material waste and reduce cycle times, thereby lowering overall manufacturing costs.

A: Automotive stamping ensures safety and reliability by producing parts with precise tolerances and consistent quality, meeting strict industry standards for performance and durability.